New Waste Regulations: Key Updates Material Recovery Facilities (MRFs) Need to Know

As of October 2024, if your Materials Recovery Facility (MRF) processes more than 1,000 tonnes of waste annually, you must sample, analyse, and report incoming and outgoing recyclables.

Along with the Simpler Recycling initiative, these changes mean that the waste streams entering your facility could change, creating new challenges. It’s time to prepare for these changes and understand how they could impact your MRF operations. Read on for more information!

WHAT IS CHANGING?

Under the new regulations, more facilities will fall under the category of Materials Facilities (MFs). It will be mandatory to sample and report the composition of the input and output waste streams. This includes:

- Materials Recovery Facilities (MRFs) sorting household dry recyclables.

- Waste Transfer Stations consolidating waste into bulk quantities.

- Frequency: The sampling frequency has increased to a 60kg sample for every 75 tonnes of incoming material, up from the previous 100 tonnes.

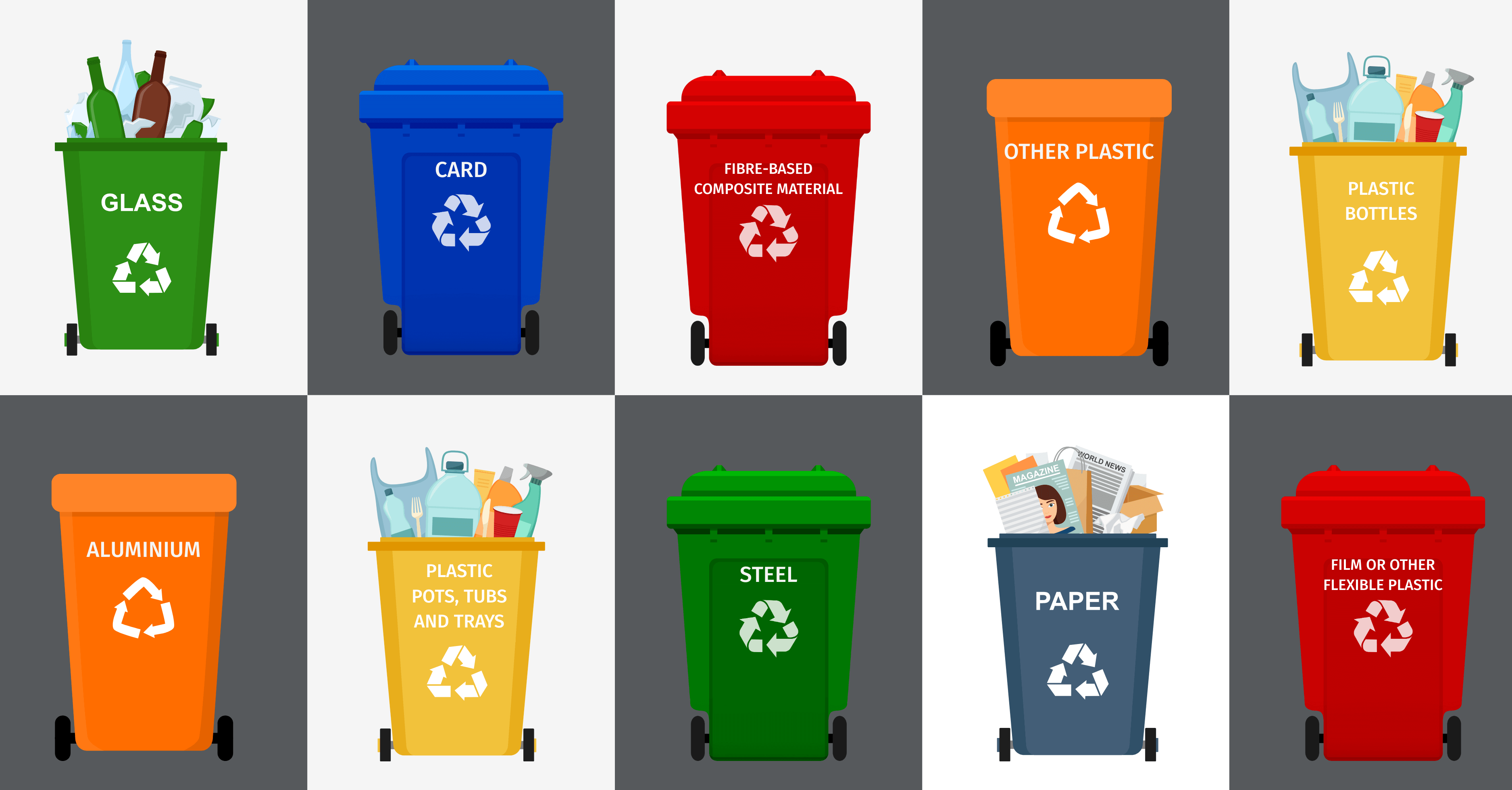

Facilities must now measure and report on 10 types of incoming waste materials, expanded from the previous four. These categories now cover the following target, non-target and non-recyclable materials:

Further to this, you must also establish whether you will need to conduct only input sampling or input and output sampling.

Input sampling refers to the sampling and measuring of incoming waste material from one or more suppliers. For input sampling, you must measure and record the following:

- the total weight in tonnes of input waste material for each supplier during each reporting period

- the name and address of the supplier (or of each supplier) for each batch of material

- the date on which the batch of material was received, from which a sample has been taken

Output sampling refers to the sampling of any specified output material produced by your MF. Operators must now record the grade and composition of specified output materials, including glass, paper, card, aluminium, steel, plastic, and fibre-based composites. The frequency and sample size will vary depending on the material type.

WHO WILL BE AFFECTED BY THESE CHANGES?

The amended regulations will affect facilities receiving single waste streams and those consolidating waste material into bulk quantities.

The amended regulations will affect:

- Materials Recovery Facilities (MRFs): Facilities receiving and processing over 1,000 tonnes of household-like waste annually.

- Transfer Stations or Waste Consolidation Facilities: Sites that bulk or consolidate waste from multiple suppliers before it is sent for further processing.

- Single Waste Stream Facilities that only process pre-sorted materials such as plastics or paper — previously exempt — will now need to carry out sampling if they meet the volume threshold.

- Third-Party Waste Handlers: Businesses that sort mixed dry recyclable materials on behalf of local authorities or private companies.

- Process single waste streams or consolidate waste into bulk quantities.

However, not all facilities are considered as MFs. For example:

- Facilities that only handle waste from a single supplier and do not separate the material into specified outputs.

- Facilities processing specific types of waste, such as electronics, batteries, or residual waste, won’t be classified as MFs.

- Local Authority provided household waste recycling centres

SO, HOW CAN YOU ENSURE YOU ARE READY?

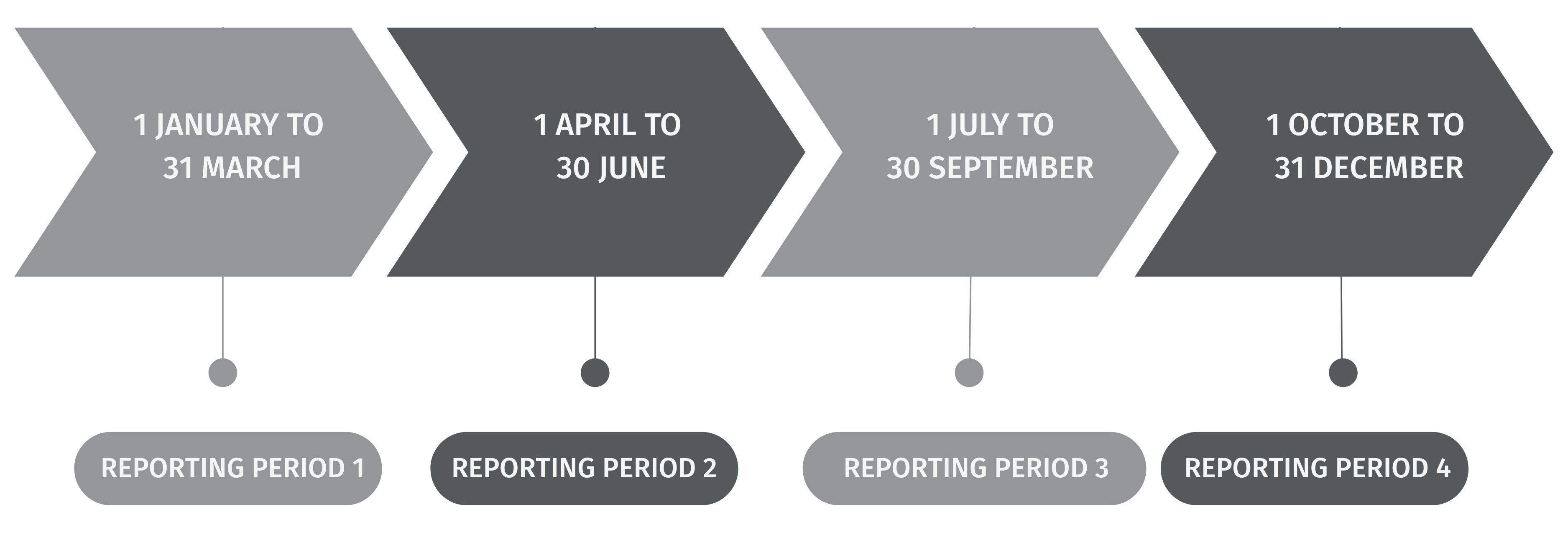

If you are a MF, you must first assess how much waste material you are likely to receive during the next 12 months. Do this at the start of each three-month reporting period. The reporting periods are:

As part of this assessment, you must consider the amount of waste material received in the previous 12 months.

If your facility handles significant volumes of waste or processes particular types of materials, these regulatory changes will likely affect you. As we move toward stricter environmental standards, businesses in the waste industry will need to adapt quickly. The new regulations are a step toward a more sustainable future, but they also mean a new level of responsibility for businesses involved in waste processing.

HOW CAN ALFRED H KNIGHT HELP?

As the changes are implemented, understanding the composition of your materials is essential. At Alfred H Knight, we have over 140 years of experience helping organisations across the waste and recycling industry.

With strategically placed hubs across the UK and a suite of independent sampling and analytical services, we can help MRFs determine the composition of their waste streams to navigate these changes whilst remaining compliant.

To find out more information, click here to speak to an expert!